Thermal Management

|

These thermally conductive products are designed to dissipate the heat out from the heat sources. This will protect the components and devices from overheating and thus prolong the operating life and enhance the performance. The Silicone Pad or the non-silicone gap filler are ideal as a conducitng media between flat surfaces. Silicone putty or grease are suitable for filling up gaps or uneven surfaces. Silicone potting have good flowability and able to fill up all the cavities to provide maximum protection to the device.

|

|

The silicone thermal pad and tape provide very good thermal conductivity up to 4.6W/mK. It can be die-cut to specific size and dimensions with thickness ranging from 0.3mm up to 5mm. It has an option with non-tacky surface or tacky surface on one or both sides of the pad/tape. Application: LED street lighting assembly. |

|||||

|

Product Code

|

Special Features

|

Appearance

|

Hardness

|

Thermal Conductivity (W/mK))

|

|

|

White | Shore 00 70-80 | 8.0 | ||

|

White | Shore 00 80-90 | 11.0 | ||

|

Pink | Shore 00 55 | 1.5 | ||

|

Light grey | Shore 00 80 | 6.0 | ||

|

Light grey | Shore 00 67 | 6.0 | ||

|

White | Shore 00 42 | 1.0 | ||

|

Blue | Shore A 10 | 0.7 | ||

|

The non-silicone thermal pad provides very good thermal conductivity up to 0.7W/mK. It can be die-cut to specific size and dimensions with thickness ranging from 0.5mm up to 4mm. It has an option with non-tacky surface or tacky surface on one or both sides of the pad/tape. Application: Set top box and LED lighting assembly.

|

|||||

|

Product Code

|

Special Features

|

Appearance

|

Hardness

|

Thermal Conductivity (W/mK))

|

|

|

Yellowish white | Shore 00 50 | 1.4 | ||

|

Yellowish white | Shore 00 42 | 2.4 | ||

|

Light Grey | Shore 00 80-90 | 11.0 | ||

|

Purple | Shore 00 70-80 | 4.1 | ||

|

White | Shore 00 70-85 | 4.2 | ||

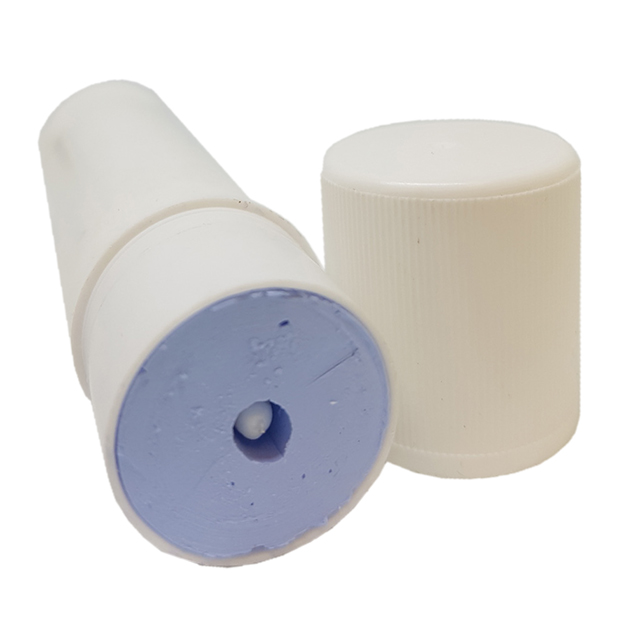

Thermal Stick Thermal StickThermal stick is a paraffin-based phase change thermally conductive compound. It is appeared in solid form at room temperature and phase change at 55ºC, allow it to wet and fill the gap on the thermal interface surface. This product supply in bar-shaped, it can be appllied on interface surface easily by hand, leaving a thin deposited thermally conductive film, providing good heat transfer and low interface thermal resistance. Application: Low to mid power tools, devices LED assembly.

|

|||||

|

Product Code

|

Special Features

|

Appearance

|

Melting Point ºC

|

Thermal Conductivity (W/mK))

|

|

|

Pale blue | 52 | 1.0 | ||

|

Non-silicone thermal putty is a non silicon based thermally conductive putty, suitable for used as thermal interface material for electronic devices. It has higher extrusion rate, low bleed and non-flow. It is designed for very good thermal conduction. Application: Low to mid power tools, devices LED assembly.

|

|||||

|

Product Code

|

Special Features

|

Appearance

|

Viscosity (cP) |

Thermal Conductivity (W/mK))

|

|

|

Light blue | 245,000 | 3.0 | ||

|

The silicone thermal putty can be easily dispensed or screen printed on most surfaces. It has excellent outdoor performance with good stability and weatherability. Application: LED lighting assembly, high power tools and devices. |

|||||

|

Product Code

|

Special Features

|

Appearance

|

Hardness

|

Thermal Conductivity (W/mK))

|

|

|

Light Grey |

0.89g/min, GA15/70psi |

4.4 | ||

|

White |

0.11g/min, GA15/80psi |

5.0 | ||

|

White | NA | 1.2 | ||

|

White | Shore A 65 | 0.85 | ||

|

Light grey |

1.43g/min,No tip/50psi |

6.8 | ||

|

The silicone thermal grease can be easily dispensed or screen printed on most surfaces. It has excellent outdoor performance with good stability and weatherability. Application: LED lighting assembly, high power tools and devices. |

|||||

|

Product Code

|

Special Features

|

Appearance

|

Viscosity (cP)

|

Thermal Conductivity (W/mK))

|

|

|

White paste | 170,000 | 2.2 | ||

|

White liquid | 150,000 |

2.5 |

||

|

White liquid | 18,500 | 1.2 | ||

|

Epoxy Adhesive

The 1-part heat curable thermal conductive epoxy has excellent adhesion and good mechanical strength that makes it suitable for bonding various types of substrates together. Application: LED lighting assembly, high power tools and devices. |

|||||

|

Product Code

|

Special Features

|

Appearance

|

Hardness

|

Thermal Conductivity (W/mK))

|

|

|

White paste | Shore D 96 | 1.1 | ||

|

Off-White | Shore D 91 | 2.3 | ||

|

Off-White | Shore D 94 | 2.6 | ||

|

Silicone Adhesive

The silicone ahhesive can be easily dispensed or screen printed on most surfaces. It has excellent outdoor performance with good stability and weatherability. Application: LED lighting assembly, high power tools and devices. |

|||||

|

Product Code

|

Special Features

|

Appearance

|

Hardness

|

Thermal Conductivity (W/mK))

|

|

|

White

|

Shore A 65

|

2.1

|

||

|

White | Shore OO 78 | 2.1 | ||

|

The 2-part Potting Silicone has good flowability and weatherability. It is self-levelling and gives good adhesion on various types of substrates like plastic and metal. Its low thermo-mechanical stress makes it suitable for potting big devices such as the display modules. Application: LED lighting assembly, high power tools and devices. |

|||||

|

Product Code

|

Special Features

|

Appearance

|

Hardness

|

Shelf Life (month)

|

Thermal Conductivity (W/mK))

|

|

Light grey | Shore A 60 | 12 | 2.0 | |

|

Light grey | Shore A 76 | 12 | 2.0 | |

|

White viscous liquid | Shore A 66 | 12 | 0.7 | |

Epoxy Potting Epoxy PottingThe 2-part Potting Epoxy has good flowability and weatherability. It is self-levelling and gives good adhesion on various types of substrates like plastic and metal. Its low thermo-mechanical stress makes it suitable for potting big devices such as the display modules. Application: LED lighting assembly, high power tools and devices. |

|||||

|

Product Code

|

Special Features

|

Appearance

|

Hardness

|

Shelf Life (month)

|

Thermal Conductivity (W/mK))

|

|

Black liquid | Shore A 65 | 12 | 1.1 | |

|

Black liquid | Shore A 80 | 12 | 1.1 | |